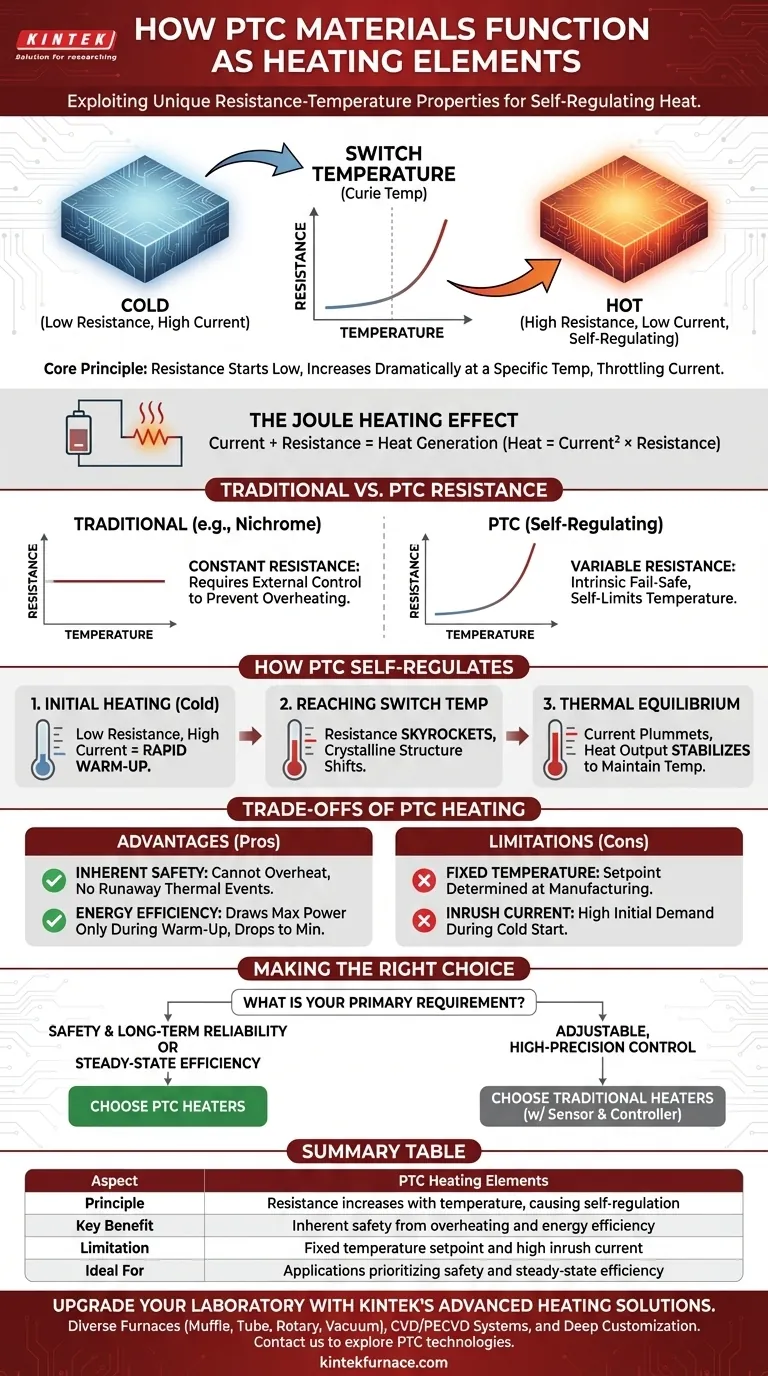

At their core, positive thermal coefficient (PTC) materials function as heating elements by exploiting a unique physical property: their electrical resistance starts low but increases dramatically upon reaching a specific temperature. This surge in resistance effectively throttles the electric current, causing the heater to self-limit its temperature without the need for external controls.

Unlike traditional heaters that require separate thermostats to prevent overheating, PTC elements have a fail-safe mechanism built directly into their material composition. This makes them inherently safer and more energy-efficient for a wide range of applications.

The Fundamental Principle: Resistive Heating

The Joule Heating Effect

All resistive heaters, including PTC elements, operate based on a principle known as the Joule heating effect. When an electric current passes through any material with electrical resistance, it generates heat.

The amount of heat produced is a function of the current squared multiplied by the resistance. This is the foundation of electric heating.

Traditional vs. PTC Resistance

A traditional heating element, like a nichrome wire, has a relatively stable and constant resistance. It will continue to generate heat and get hotter as long as power is applied, creating a risk of overheating unless managed by an external sensor and controller.

PTC materials behave differently. Their resistance is not constant; it is directly and dramatically linked to their temperature.

How PTC Materials Self-Regulate

The Initial Heating Phase

When a PTC heater is cold, its electrical resistance is very low. This allows a relatively high current to flow through it, causing rapid heat generation and a quick warm-up period.

Reaching the "Switch" Temperature

Every PTC material is engineered with a specific "switch" temperature, often referred to as the Curie temperature. As the material heats up and approaches this critical temperature, its internal crystalline structure shifts.

This structural change causes the electrical resistance to skyrocket, often by several orders of magnitude, in a very narrow temperature range.

Achieving Thermal Equilibrium

This sharp increase in resistance drastically reduces the current flowing through the element. Since heat generation is dependent on current, the heat output plummets.

The element stops getting hotter and settles into a state of thermal equilibrium. It produces just enough heat to compensate for what is lost to the surrounding environment, effectively maintaining a stable operating temperature.

Understanding the Trade-offs of PTC Heating

The Advantage: Inherent Safety

The most significant benefit of PTC technology is its inherent safety. Because it is physically incapable of overheating beyond its design temperature, the risk of fire or damage from a runaway thermal event is virtually eliminated. This simplifies design and increases product reliability.

The Advantage: Energy Efficiency

PTC heaters are highly efficient in steady-state operation. They draw maximum power only during the initial warm-up. Once at temperature, their power consumption automatically drops to the minimum level needed to maintain it, avoiding wasted energy.

The Limitation: Fixed Temperature Setpoint

The self-regulating temperature is an intrinsic property of the PTC material itself. You cannot easily adjust this setpoint; it is determined during the manufacturing process. Applications requiring variable temperature control may be better served by traditional systems.

The Limitation: Inrush Current

During a cold start, the very low initial resistance of a PTC element can cause a high inrush current. Your power supply and circuit protection must be designed to handle this brief, high-power demand without failing.

Making the Right Choice for Your Application

Choosing between a PTC and a traditional resistive heater depends entirely on your project's non-negotiable requirements.

- If your primary focus is safety and long-term reliability: PTC heaters are the superior choice due to their built-in self-regulating properties that prevent overheating.

- If your primary focus is minimizing energy consumption in a steady-state system: PTC heaters excel by automatically reducing power draw once the target temperature is reached.

- If your primary focus is adjustable, high-precision temperature control: A traditional resistive element paired with a sensor and PID controller offers greater flexibility.

By understanding this fundamental principle of self-regulation, you can confidently select the heating technology that best aligns with your design goals.

Summary Table:

| Aspect | PTC Heating Elements |

|---|---|

| Principle | Resistance increases with temperature, causing self-regulation |

| Key Benefit | Inherent safety from overheating and energy efficiency |

| Limitation | Fixed temperature setpoint and high inrush current |

| Ideal For | Applications prioritizing safety and steady-state efficiency |

Upgrade Your Laboratory with KINTEK's Advanced Heating Solutions

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capability to precisely meet unique experimental requirements. If you're targeting enhanced safety, energy efficiency, or tailored heating for your projects, contact us today to explore how our PTC and other heating technologies can drive your success!

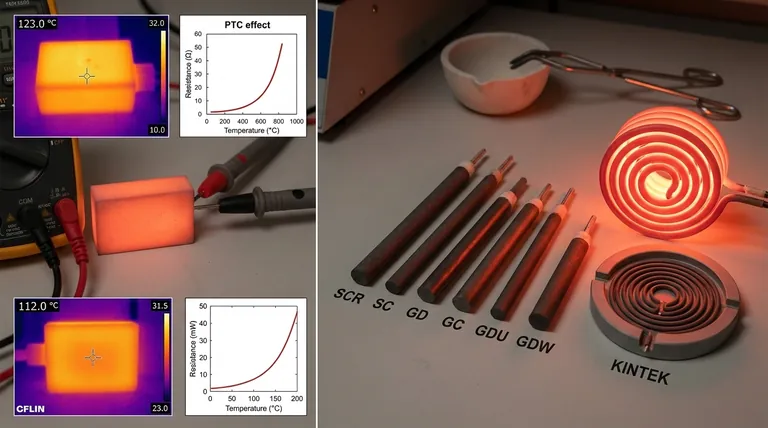

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Molybdenum Disilicide MoSi2 Thermal Heating Elements for Electric Furnace

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

People Also Ask

- What makes silicon carbide heating elements resistant to chemical corrosion? Discover the Protective Oxide Layer

- Why are SIC heating elements resistant to chemical corrosion? Discover the Self-Protecting Mechanism

- Why are silicon carbide heating elements essential in high-temperature industries? Unlock Reliable, Extreme Heat Solutions

- What is the maximum temperature silicon carbide heating elements can withstand? Key Factors for Longevity and Performance

- What are the properties and capabilities of Silicon Carbide (SiC) as a heating element? Unlock Extreme Heat and Durability