Yes, quartz tubes are highly customizable. They can be manufactured to precise specifications in terms of size, shape, and wall thickness to meet the unique demands of scientific and industrial applications. This adaptability allows them to be used not just as simple tubes, but also as specialized components like end caps, process carriers, or reaction vessels for high-temperature furnaces.

The ability to customize quartz tubes is not merely about physical fit; it is about strategically leveraging the material's exceptional purity, thermal resistance, and chemical inertness to create a precisely controlled environment for a specific process.

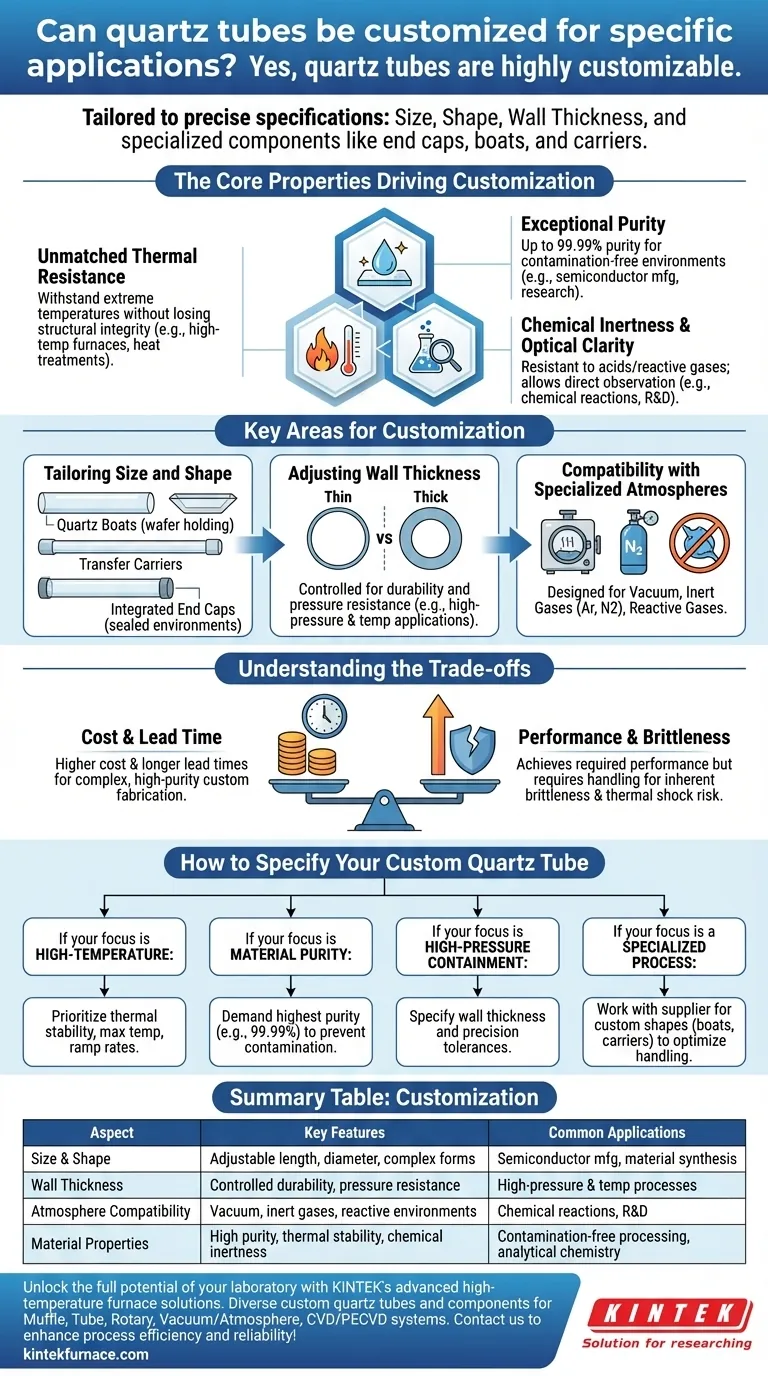

The Core Properties Driving Customization

The demand for custom quartz components stems from the material's unique combination of properties, which are critical for advanced processes. Understanding these properties is key to specifying the right customization for your goal.

Unmatched Thermal Resistance

Quartz exhibits excellent thermal stability, allowing it to withstand extreme temperatures without losing its structural integrity. This makes custom tubes essential for high-temperature furnace processes, heat treatments, and material synthesis.

Exceptional Purity for Contamination-Free Environments

With purity levels often reaching 99.99%, quartz is one of the purest materials available. This ensures that samples are not contaminated during processing, a non-negotiable requirement in semiconductor manufacturing, materials science research, and analytical chemistry.

Chemical Inertness and Optical Clarity

Quartz is resistant to most acids and reactive gases, making it an ideal container for chemical reactions under harsh conditions. Its optical clarity also allows for direct observation of processes, which is invaluable in research and development settings.

Key Areas for Customization

Customization goes beyond simple dimensions. It involves creating a component perfectly suited to a specific apparatus and process environment.

Tailoring Size and Shape

Suppliers can modify the length, diameter, and overall shape of a quartz tube. This includes producing complex forms like quartz boats for holding wafers, transfer carriers, or tubes with integrated end caps for sealed environments.

Adjusting Wall Thickness

The thickness of the tube wall can be precisely controlled. Thicker walls provide greater durability and resistance to high-pressure conditions, making them suitable for applications requiring both high temperatures and pressures.

Compatibility with Specialized Atmospheres

Custom quartz tubes are designed to function reliably in various controlled atmospheres. This includes high vacuum, inert gas environments like argon or nitrogen, and atmospheres containing reactive gases.

Understanding the Trade-offs

While highly versatile, customizing quartz involves practical considerations that must be balanced against application requirements.

Cost vs. Performance

Custom fabrication is inherently more expensive than using standard, off-the-shelf components. The cost increases with complexity, tighter tolerances, and higher purity grades, but this investment is often necessary to achieve the required process performance and reliability.

Lead Time and Manufacturing Complexity

Specialized quartz components require longer lead times for design, fabrication, and quality control. Complex shapes or features demand advanced manufacturing techniques, which can extend production timelines.

Material Brittleness

Despite its high thermal and chemical resistance, quartz is a ceramic material and is inherently brittle. Custom designs must account for potential mechanical stress and the risk of thermal shock (cracking from rapid temperature changes) to ensure longevity.

How to Specify Your Custom Quartz Tube

To ensure the final product meets your needs, clearly define your primary operational goal.

- If your primary focus is high-temperature processing: Prioritize thermal stability and specify the maximum operating temperature and required ramp rates.

- If your primary focus is material purity: Demand the highest purity grade (e.g., 99.99%) to prevent sample contamination in semiconductor or research applications.

- If your primary focus is high-pressure containment: Specify the required wall thickness and precision tolerances needed to safely withstand your process pressures.

- If your primary focus is a specialized process: Work with your supplier to design custom shapes, such as boats or carriers, that optimize material handling within your furnace.

By clearly defining your requirements, you can leverage the full potential of custom quartz fabrication for your specific application.

Summary Table:

| Customization Aspect | Key Features | Common Applications |

|---|---|---|

| Size and Shape | Adjustable length, diameter, complex forms (e.g., boats, end caps) | Semiconductor manufacturing, material synthesis |

| Wall Thickness | Controlled for durability and pressure resistance | High-pressure and high-temperature processes |

| Atmosphere Compatibility | Designed for vacuum, inert gases, reactive environments | Chemical reactions, research and development |

| Material Properties | High purity (up to 99.99%), thermal stability, chemical inertness | Contamination-free processing, analytical chemistry |

Unlock the full potential of your laboratory with KINTEK's advanced high-temperature furnace solutions. Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with custom quartz tubes and components tailored to your unique needs. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capabilities to precisely meet your experimental requirements. Contact us today to discuss how we can enhance your process efficiency and reliability!

Visual Guide

Related Products

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- What are the key features of a quartz tube furnace? Discover High-Temp Precision for Your Lab

- What is the difference between an alumina tube furnace and a quartz tube furnace? Choose the Right Tube Furnace for Your Lab

- What is a Quartz Tube Furnace and what is its primary function? Essential for Real-Time Material Observation

- What is a quartz tube furnace and what is its primary use? Essential for Controlled High-Temp Processing

- How should a quartz tube furnace be cleaned? Essential Steps for Safe, Contamination-Free Maintenance