In modern restorative dentistry, porcelain etch is used to microscopically roughen the fitting surface of a ceramic restoration—such as a crown, veneer, or inlay—before it is bonded to a tooth. This chemical preparation is a critical step that transforms the smooth, inert porcelain into a surface that can form a strong, permanent mechanical bond with dental adhesives.

The core challenge with dental porcelain is that its beautiful, glass-like surface is too smooth for adhesives to grip effectively. Porcelain etch solves this by dissolving specific components of the ceramic, creating a microscopic, textured landscape that allows bonding agents to lock in place, ensuring the longevity of the restoration.

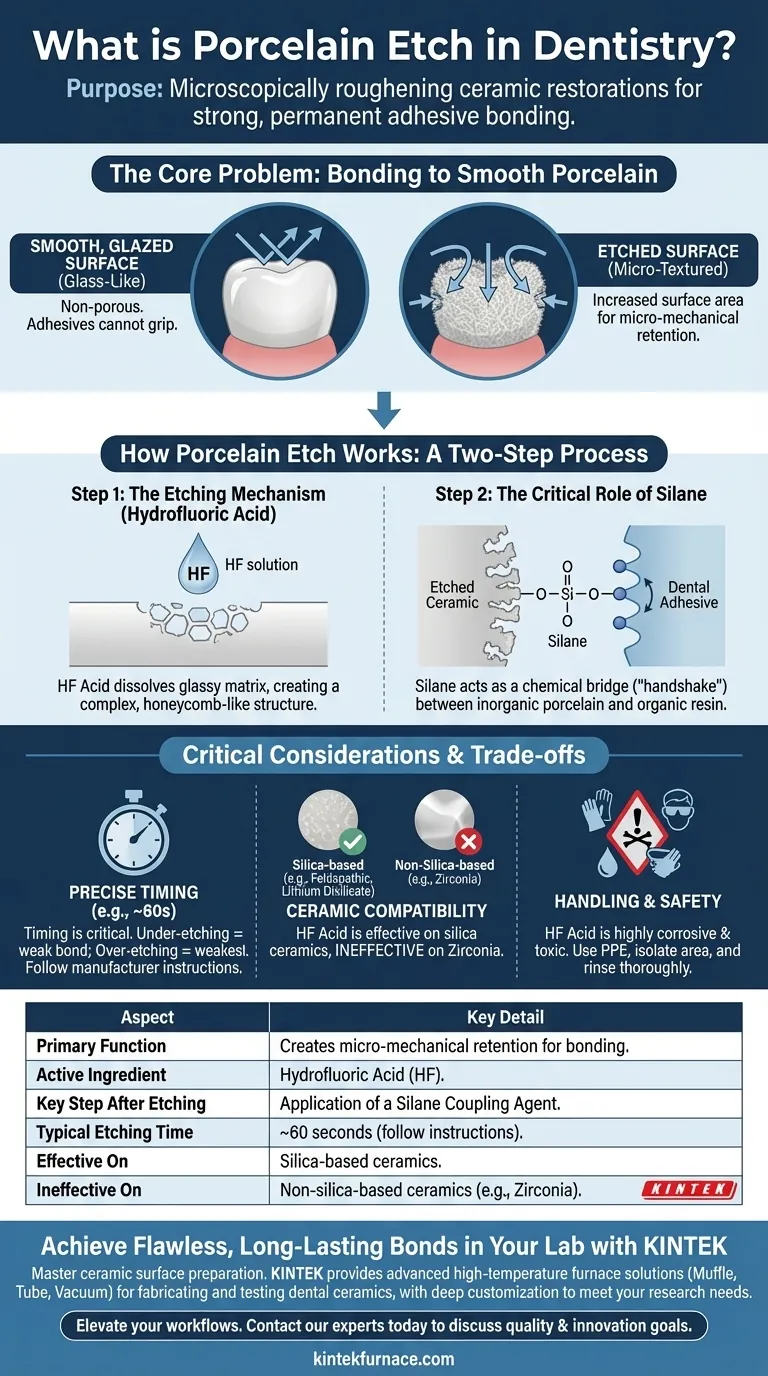

The Core Problem: Bonding to a Glass-Like Surface

The very properties that make dental porcelain an excellent restorative material also make it difficult to bond. Understanding this paradox is key to appreciating the function of porcelain etch.

The Smooth Nature of Dental Porcelain

Dental porcelain is a type of ceramic prized for its biocompatibility, strength, and natural, tooth-like appearance.

During fabrication, restorations are often glazed, which involves applying a thin layer of glass that is fired to create an exceptionally smooth, dense, and stain-resistant outer surface.

Why Smoothness Prevents Adhesion

Adhesive bonding relies heavily on micro-mechanical retention. The adhesive needs to flow into microscopic nooks and crannies and then harden, creating a physical interlock, much like Velcro.

A glazed porcelain surface is non-porous and lacks this texture. Applying a bonding agent directly to it would result in a weak, superficial connection highly prone to failure.

How Porcelain Etch Creates a Bondable Surface

Porcelain etch chemically alters the smooth ceramic, creating the ideal topography for a durable adhesive bond. The process is a one-two punch of chemical etching followed by a chemical coupling agent.

The Etching Mechanism

Porcelain etch is a solution of hydrofluoric acid (HF). When applied to the restoration's fitting surface, it selectively dissolves the glassy matrix of the ceramic material.

This controlled dissolution does not happen uniformly. It preferentially removes certain components, leaving behind a complex, three-dimensional, honeycomb-like structure.

Creating Micro-Mechanical Retention

The resulting etched surface has a dramatically increased surface area, filled with microscopic undercuts and pores.

This texture provides the necessary mechanical grip for a resin bonding agent to flow into, interlock with, and cure. This is the primary mechanism that creates a powerful and predictable bond.

The Critical Role of Silane

After etching and rinsing, a silane coupling agent is applied. Silane acts as a chemical bridge or "handshake" between the inorganic porcelain and the organic resin cement.

One end of the silane molecule bonds to the etched ceramic surface, while the other end co-reacts and bonds with the dental adhesive. This combination of micro-mechanical etching and chemical silane coupling creates the strongest possible bond.

Understanding the Trade-offs and Critical Steps

While essential, the use of porcelain etch is a technique-sensitive procedure that requires precision. Mistakes can compromise both the bond strength and the integrity of the restoration.

The Importance of Precise Timing

As stated in clinical guidelines, the application is often timed for around 60 seconds. Under-etching will fail to create sufficient texture, leading to a weak bond.

Conversely, over-etching can dissolve too much of the ceramic structure, potentially weakening the porcelain and leading to fractures over time. Always follow the specific manufacturer's instructions for the ceramic being used.

Not All Ceramics Are the Same

Hydrofluoric acid is effective on silica-based ceramics like feldspathic porcelain and lithium disilicate.

However, it is ineffective on high-strength, non-silica-based ceramics like zirconia. These materials require different surface preparation methods, such as sandblasting, and specialized primers. Using the wrong technique will result in bond failure.

Handling and Safety Protocols

Hydrofluoric acid is highly corrosive and toxic. It must be handled with extreme care.

Proper clinical protocol involves isolating the work area, using personal protective equipment (PPE), and ensuring immediate and thorough rinsing and suction to protect both the patient and the dental team from chemical burns.

Making the Right Choice for Your Goal

Properly etching a porcelain restoration is not just a step; it's the foundation for its success. Your approach should align with your primary clinical objective.

- If your primary focus is bond longevity: Treat etching and silanating as an inseparable pair. The micro-mechanical retention from the etch is only fully leveraged when a silane coupling agent is used to bridge the gap to the resin cement.

- If your primary focus is aesthetics: A strong, sealed margin is your best defense against future staining and leakage. Perfecting the etch prevents micro-gaps where discoloration can begin, preserving the restoration's beauty.

- If your primary focus is procedural safety: Prepare your complete setup—including acid, timer, high-volume suction, and rinsing water—before ever touching the restoration. Control of the material is paramount.

Mastering the surface preparation of porcelain is the foundation for creating beautiful and durable dental restorations that stand the test of time.

Summary Table:

| Aspect | Key Detail |

|---|---|

| Primary Function | Creates micro-mechanical retention for bonding. |

| Active Ingredient | Hydrofluoric Acid (HF). |

| Key Step After Etching | Application of a Silane Coupling Agent. |

| Typical Etching Time | Approximately 60 seconds (follow manufacturer's instructions). |

| Effective On | Silica-based ceramics (e.g., feldspathic porcelain, lithium disilicate). |

| Ineffective On | Non-silica-based ceramics (e.g., Zirconia). |

Achieve Flawless, Long-Lasting Bonds in Your Lab

Mastering precise ceramic surface preparation is critical for successful dental restorations. At KINTEK, we understand the exacting standards of dental laboratories. Leveraging exceptional R&D and in-house manufacturing, we provide advanced high-temperature furnace solutions for fabricating and testing these vital ceramic components.

Our product line, including Muffle, Tube, and Vacuum Furnaces, is complemented by strong deep customization capabilities to precisely meet your unique ceramic processing and research requirements.

Elevate your dental ceramic workflows. Contact our experts today to discuss how our solutions can support your quality and innovation goals.

Visual Guide

Related Products

- Vacuum Dental Porcelain Sintering Furnace for Dental Laboratories

- Vacuum Hot Press Furnace Machine for Lamination and Heating

People Also Ask

- What are some recent innovations in dental lab equipment furnaces? Boost Efficiency with Smart Automation

- What is the use of porcelain in dentistry? Achieve Lifelike, Durable Dental Restorations

- How does an efficient cooling system benefit dental furnace operations? Boost Productivity and Quality in Your Lab

- What is the main purpose of a sintering furnace in dentistry? Transform Zirconia into Strong Dental Restorations

- How does precise temperature control in a porcelain furnace benefit sintering? Achieve Perfect Dental Restorations