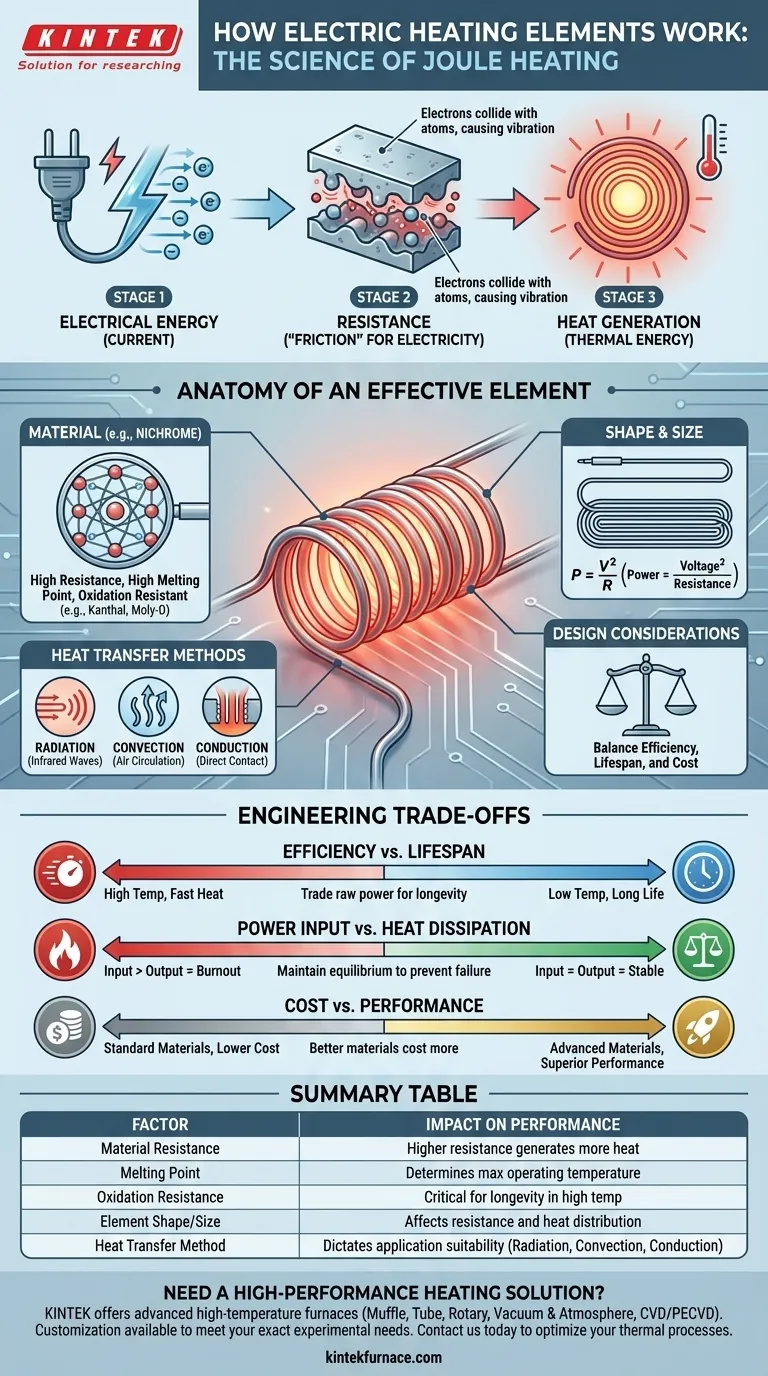

At its core, an electric heating element works by converting electrical energy directly into heat through a process called Joule heating. This occurs when an electric current flows through a material that is specifically chosen for its high electrical resistance. The resistance acts like friction against the current, forcing the electrical energy to be released as thermal energy.

The effectiveness of a heating element is not accidental; it is a deliberate engineering choice. The key is to use a material that actively resists the flow of electricity, causing controlled "friction" that generates heat, and then to design its shape to manage and radiate that heat effectively.

The Fundamental Principle: Joule Heating

The science behind every electric stove, water heater, and space heater is remarkably straightforward. It all comes down to controlling how electricity behaves when it encounters an obstacle.

What is Electrical Resistance?

Think of electrical resistance as friction for electricity. If a copper wire is like a wide-open highway for electric current, a resistive material is like a narrow, bumpy road.

The material’s atoms get in the way of the flowing electrons. This opposition to the free flow of current is what we call resistance.

From Current to Heat

When you force an electric current through a high-resistance material, the flowing electrons constantly collide with the atoms of that material.

Each collision transfers energy from the electron to the atom, causing the atom to vibrate more intensely. This increased atomic vibration is what we perceive and measure as heat.

Anatomy of an Effective Heating Element

The design of a heating element is a careful balance of material science, electrical principles, and thermal dynamics to produce and deliver heat reliably.

The Critical Role of Material

The choice of material is paramount. An ideal material has high electrical resistance to generate heat efficiently and a high melting point to survive its own operation.

Most importantly, it must resist oxidation (reacting with air) at high temperatures. This is why alloys like Nichrome (nickel-chromium) are so common; they form a protective outer layer of chromium oxide that prevents them from burning out quickly.

The Importance of Shape and Size

The physical dimensions of the element are calculated to achieve a specific resistance. According to the formula P = V²/R (Power = Voltage² / Resistance), the element's resistance (R) directly determines how much power (and thus heat) it produces at a given voltage (V).

This is why heating elements are often long, thin wires or ribbons, as this shape increases resistance. They are frequently coiled to fit a large length into a compact space, maximizing heat generation in a small area.

Transferring the Heat

Once heat is generated, it must be moved to where it is needed. The primary method is thermal radiation, where the hot element emits infrared energy that heats objects directly without touching them, like the sun warming your face.

Heat is also transferred through convection (heating the surrounding air, which then circulates) and conduction (direct physical contact).

Understanding the Trade-offs

Designing a heating element involves compromises. Optimizing for one characteristic often means sacrificing another.

Efficiency vs. Lifespan

Running an element at a very high temperature produces a lot of heat quickly. However, high temperatures dramatically accelerate material degradation and oxidation, significantly shortening the element's operational life.

A more durable design might operate at a lower temperature, trading raw power for longevity.

Power Input vs. Heat Dissipation

An element can only survive if the heat it generates is removed at the same rate. If the power input (from electricity) is greater than the heat output (through radiation, convection, etc.), the element's temperature will rise uncontrollably.

This imbalance is a primary cause of failure, leading to the element melting or burning out. Proper design ensures this equilibrium is maintained during normal operation.

Cost vs. Performance

Materials that can withstand extreme temperatures and harsh chemical environments, such as Kanthal (iron-chromium-aluminum) or molybdenum disilicide, offer superior performance and lifespan. However, these advanced materials come at a much higher cost than standard Nichrome.

Making the Right Choice for Your Goal

The "best" heating element is entirely dependent on the specific application. Understanding the core principles allows you to evaluate them based on your primary objective.

- If your primary focus is rapid heating: You need an element designed for high power density, which often means operating at a higher temperature and accepting a shorter lifespan.

- If your primary focus is long-term reliability: You should select an element made from high-grade, oxidation-resistant materials that will be operated well below its maximum temperature limit.

- If your primary focus is precise temperature control: The system requires not just a well-designed element, but also an external control loop (like a thermostat or PID controller) to modulate power input and maintain a stable temperature.

By understanding these principles, you can transform a simple heating element from a black box into a predictable and controllable engineering component.

Summary Table:

| Factor | Impact on Performance |

|---|---|

| Material Resistance | Higher resistance generates more heat per unit current. |

| Melting Point | Determines maximum operating temperature and lifespan. |

| Oxidation Resistance | Critical for longevity in high-temperature environments. |

| Element Shape/Size | Affects resistance, power output, and heat distribution. |

| Heat Transfer Method | Radiation, convection, or conduction dictates application suitability. |

Need a high-performance heating solution tailored to your lab's unique requirements? At KINTEK, we leverage our exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions. Whether you need rapid heating, long-term reliability, or precise temperature control, our product line—including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems—is backed by deep customization capabilities to meet your exact experimental needs. Contact us today to discuss how we can optimize your thermal processes!

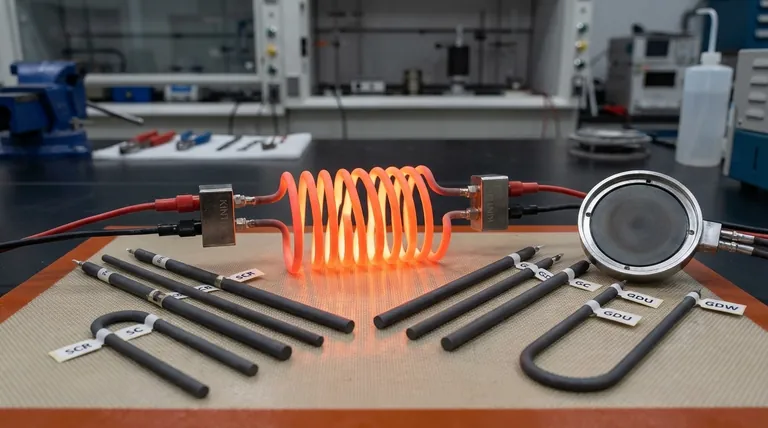

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

People Also Ask

- Why are SIC heating elements resistant to chemical corrosion? Discover the Self-Protecting Mechanism

- What are the properties and capabilities of Silicon Carbide (SiC) as a heating element? Unlock Extreme Heat and Durability

- What makes SIC heating elements superior for high-temperature applications? Unlock Efficiency and Durability

- Why is silicon carbide resistant to chemical reactions in industrial furnaces? Unlock Durable High-Temp Solutions

- What are the advantages of using high purity green silicon carbide powder in heating elements? Boost Efficiency and Lifespan