Thermal Elements

Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

Item Number : KT-SH

Price varies based on specs and customizations

- Operating Temperature Range

- 600°C to 1600°C

- Resistance Range

- 0.3-8.6 ohms

- Thermal Conductivity

- 14-19W/m·K (at 1000°C)

Shipping:

Contact us to get shipping details Enjoy On-time Dispatch Guarantee.

Why Choose Us

Reliable PartnerEasy ordering process, quality products, and dedicated support for your business success.

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD/MPCVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements.

As a core component for achieving precise and reliable high temperatures in these systems and beyond, our Silicon Carbide (SiC) Heating Elements embody this commitment to quality, performance, and tailored solutions.

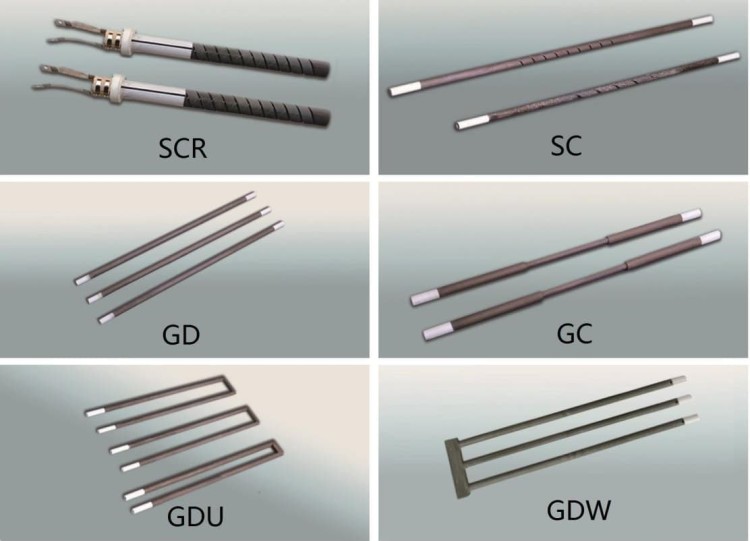

Visual Showcase: Our SiC Heating Elements

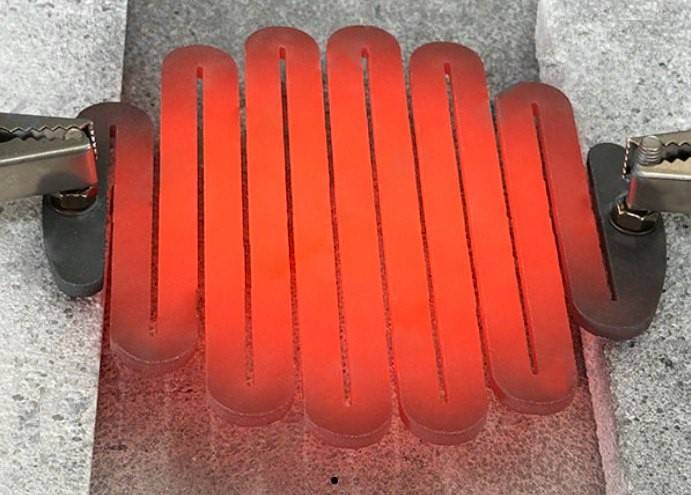

Understanding Silicon Carbide (SiC) Heating Elements

Silicon Carbide (SiC) Heating Elements are high-performance ceramic devices essential for electric furnaces operating at extreme temperatures. Renowned for their high electrical conductivity and exceptional resistance to heat, these elements are manufactured from a specialized compound of silicon and carbon. Formed through a recrystallization process at temperatures exceeding 2150°C, SiC heating elements offer remarkable longevity and energy efficiency. They are incredibly versatile, available in various configurations, and ideally suited for applications requiring temperatures from 600°C to 1600°C, making them indispensable in industries like metallurgy, ceramics, and semiconductor manufacturing.

Why Choose KINTEK's SiC Heating Elements? Key Advantages

KINTEK's Silicon Carbide (SiC) heating elements offer numerous advantages, making them a superior choice for a wide array of high-temperature applications. Our elements, crafted from the hard ceramic compound carborundum (silicon and carbon), ensure high electrical conductivity and exceptional durability.

- High-Temperature Performance: Operate efficiently at temperatures ranging from 600°C to 1600°C, perfect for demanding high-temperature furnaces and processes.

- Energy Efficiency: Feature a small hot-end resistance, leading to significant energy savings by minimizing wasted heat and boosting overall heating system efficiency.

- Long Service Life: Robust ceramic construction ensures a longer lifespan compared to other heating elements, especially in corrosive or challenging environments.

- Precise Temperature Control: Achieve accurate and stable temperature control, crucial for enhancing the quality and consistency of your products and experimental outcomes.

- Safety and Environmental Benefits: Eliminate the need for flue gases, improving workplace safety and reducing environmental impact, contributing to a cleaner working environment.

- Versatility in Design: Available in multiple configurations, our SiC heating elements can be tailored to specific applications, extending their life and effectiveness.

- Cost-Effectiveness: While offering premium performance, SiC elements provide long-term savings through superior energy efficiency and extended lifespan, reducing overall operational costs.

- Enhanced Power Radiation: Capable of radiating higher power, beneficial for processes requiring rapid heating or maintaining high-temperature stability.

With KINTEK's deep customization capability, we can tailor SiC heating elements to your precise experimental needs. Discuss your requirements with our experts today.

Versatile Applications

SiC heating elements are widely utilized across machinery, metallurgy, light chemicals, ceramics, semiconductors, analytical testing, scientific research, and more, serving as the primary electric heating component in various electric furnaces and kilns such as tunnel kilns, roller kilns, glass kilns, vacuum furnaces, muffle furnaces, smelting furnaces, and diverse heating equipment. Key application areas include:

- Metallurgy: Crucial for smelting, refining, and heat treatment processes in metal production.

- Ceramics: Essential for firing and sintering, ensuring uniform heating and high-quality ceramic products.

- Glass Manufacturing: Vital for melting and shaping glass, requiring consistent and precise high temperatures.

- Chemical Processing: Used in chemical reactors and processing units demanding controlled high-temperature environments.

- Laboratory Furnaces: Integral to scientific research and analytical testing furnaces for various high-temperature experiments.

- Semiconductor Fabrication: Provides the precise temperature control necessary for semiconductor and electronic component production.

- Environmental Testing: Employed in chambers that simulate extreme temperature conditions for product durability testing.

- Food Processing: Used in industrial ovens and equipment requiring high-temperature processing.

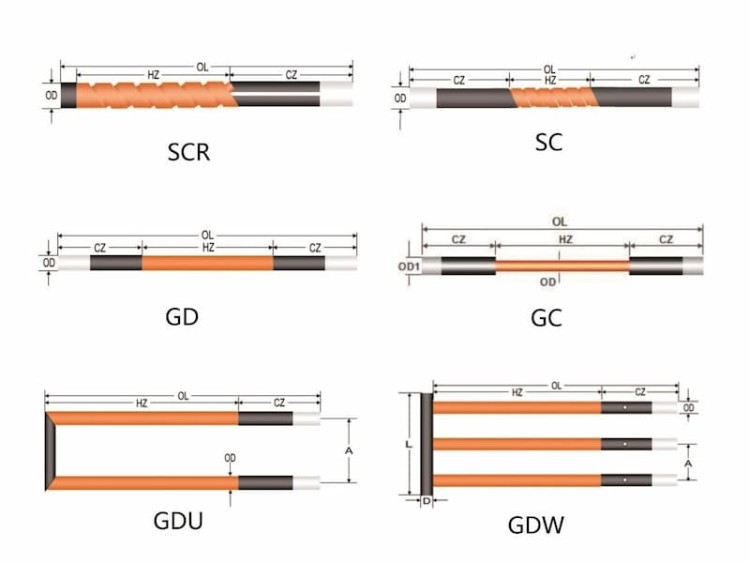

Customization & Sizing: Finding Your Perfect Fit

We understand that unique experiments require specific solutions. KINTEK offers a range of SiC heating elements and the expertise to help you select or customize the perfect fit for your high-temperature application.

How to Specify Your SiC Heating Element Model

- OD: Outer diameter

- HZ: Hot zone length

- CZ: Cold zone length

- OL: Overall length

Example: For an SCR type element with OD = 8 mm, HZ = 100 mm, CZ = 130 mm, OL = 230 mm, and Resistance 4.46 ohms, you can specify its model as: 8*100*230 / 4.46 ohms.

Standard SiC Heating Element Availability:

| OD | HZ | CZ | OL | Resistance |

| 8mm | 100-300mm | 60-200mm | 240-700mm | 2.1-8.6 ohms |

| 12mm | 100-400mm | 100-350mm | 300-1100mm | 0.8-5.8 ohms |

| 14mm | 100-500mm | 150-350mm | 400-1200 | 0.7-5.6 ohms |

| 16mm | 200-600mm | 200-350mm | 600-1300 | 0.7-4.4 ohms |

| 18mm | 200-800mm | 200-400mm | 600-1600 | 0.7-5.8 ohms |

| 20mm | 200-800mm | 250-600mm | 700-2000mm | 0.6-6.0 ohms |

| 25mm | 200-1200mm | 250-700mm | 700-2600mm | 0.4-5.0 ohms |

| 30mm | 300-2000mm | 250-800mm | 800-3600mm | 0.4-4.0 ohms |

| 35mm | 400-2000mm | 250-800mm | 900-3600mm | 0.5-3.6 ohms |

| 40mm | 500-2700mm | 250-800mm | 1000-4300mm | 0.5-3.4 ohms |

| 45mm | 500-3000mm | 250-750mm | 1000-4500mm | 0.3-3.0 ohms |

| 50mm | 600-2500mm | 300-750mm | 1200-4000mm | 0.3-2.5 ohms |

| 54mm | 600-2500mm | 300-750mm | 1200-4000mm | 0.3-3.0 ohms |

Need a specific configuration not listed or unsure which SiC heating element is right for your application? Leverage KINTEK's expertise in deep customization. Contact us via the form below to detail your unique experimental requirements and receive a personalized solution.

Technical Specifications

Physical Properties

| Bulk Density | 2.5g/cm³ |

| Porosity | 23% |

| Thermal Conductivity | 14-19W/m·K (at 1000°C) |

| Rupture Strength | 50MPa (at 25°C) |

| Specific Heat | 1.0kJ/kg·K (at 25~1300°C) |

| Coefficient Of Thermal Expansion | 4.5 × 10⁻⁶ /K |

Chemical Properties

Silicon carbide heating elements exhibit good chemical stability and strong acid resistance. However, at high temperatures, alkaline substances can cause erosion.

Long-term use of silicon carbide elements above 1000°C can lead to reactions with oxygen and water vapor:

① SiC + 2O₂ → SiO₂ + CO₂

② SiC + 4H₂O → SiO₂ + 4H₂ + CO₂

Consequently, the SiO₂ content in the element gradually increases, and its resistance slowly rises, leading to aging. Excessive water vapor can accelerate SiC oxidation. The H₂ generated from reaction ② can combine with O₂ in the air, reforming H₂O and creating a detrimental cycle that reduces component life. Hydrogen (H₂) can also reduce the mechanical strength of components. Nitrogen (N₂) below 1200°C can prevent SiC oxidation; above 1350°C, it can react with SiC, causing decomposition. Chlorine (Cl₂) can completely decompose SiC.

Installation Guidance

Proper installation is key to maximizing the performance and lifespan of your SiC heating elements. For detailed instructions and best practices, please refer to our guide: Precautions for Installing Silicon Carbide Rods.

For further assistance, custom configurations, or to discuss your specific high-temperature furnace needs, please contact our KINTEK specialists using the form below. We are ready to help you achieve optimal results.

FAQ

What Are The Main Applications Of Heater Elements Like MoSi2 And SiC?

What Are The Advantages Of Using MoSi2 Heating Elements?

What Are The Benefits Of SiC Heating Elements?

Why Are Ceramic And Semiconductor Heating Elements Like MoSi2 And SiC Suitable For High-temperature Environments?

Can MoSi2 And SiC Heating Elements Be Customized?

4.8

out of

5

Incredible durability! These elements outlasted all others I've tried. Worth every penny!

4.9

out of

5

Fast shipping and top-notch quality. My furnace runs smoother than ever!

4.7

out of

5

Superior heat resistance and efficiency. A game-changer for my lab!

4.9

out of

5

Precision engineering at its finest. These elements are a cut above the rest.

4.8

out of

5

Exceptional value for money. They’ve drastically reduced my energy costs!

4.7

out of

5

Reliable and robust. Perfect for high-temperature applications.

4.9

out of

5

Tech-savvy and efficient. My furnace has never performed better!

4.8

out of

5

Quick delivery and flawless performance. Highly recommended!

4.7

out of

5

These elements are built to last. A fantastic investment!

4.9

out of

5

Cutting-edge technology. My furnace heats up faster and more evenly now.

4.8

out of

5

Outstanding quality and performance. Exceeded all my expectations!

4.7

out of

5

Durable and efficient. Perfect for industrial use.

4.9

out of

5

Worth every cent! These elements have revolutionized my workflow.

4.8

out of

5

Fast, reliable, and high-quality. Couldn’t be happier!

4.7

out of

5

Consistent performance and long lifespan. A must-have!

4.9

out of

5

Top-tier technology. My furnace operates at peak efficiency now.

4.8

out of

5

Excellent heat distribution and durability. Highly impressed!

4.7

out of

5

Affordable yet high-performance. A stellar purchase!

4.9

out of

5

Simply the best. These elements have transformed my furnace’s output!

REQUEST A QUOTE

Our professional team will reply to you within one business day. Please feel free to contact us!

Related Products

Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant Rotating Furnace

KINTEK's Rotary Biomass Pyrolysis Furnace converts biomass to biochar, bio-oil, and syngas efficiently. Customizable for research or production. Get your solution now!

Molybdenum Vacuum Heat Treat Furnace

High-performance molybdenum vacuum furnace for precise 1400°C heat treatment. Ideal for sintering, brazing, and crystal growth. Durable, efficient, and customizable.

Stainless Steel KF ISO Vacuum Flange Blind Plate for High Vacuum Systems

Premium KF/ISO stainless steel vacuum blind plates for high-vacuum systems. Durable 304/316 SS, Viton/EPDM seals. KF & ISO connections. Get expert advice now!

Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

KINTEK's RTP Rapid Heating Tube Furnace delivers precise temperature control, rapid heating up to 100°C/sec, and versatile atmosphere options for advanced lab applications.

Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

Discover KINTEK's advanced Vacuum Tube Hot Press Furnace for precise high-temperature sintering, hot pressing, and material bonding. Customizable solutions for labs.

Vacuum Hot Press Furnace Machine for Lamination and Heating

KINTEK Vacuum Lamination Press: Precision bonding for wafer, thin-film & LCP applications. 500°C max temp, 20-ton pressure, CE certified. Custom solutions available.

Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

KINTEK's Vacuum Molybdenum Wire Sintering Furnace excels in high-temperature, high-vacuum processes for sintering, annealing, and material research. Achieve precise 1700°C heating with uniform results. Custom solutions available.

Vacuum Hot Press Furnace Machine Heated Vacuum Press

KINTEK Vacuum Hot Pressing Furnace: Precision heating & pressing for superior material density. Customizable up to 2800°C, ideal for metals, ceramics, and composites. Explore advanced features now!

Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

KINTEK's Multi-Zone CVD Tube Furnaces offer precision temperature control for advanced thin film deposition. Ideal for research and production, customizable for your lab needs.

Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

KINTEK's CVD Tube Furnace offers precision temperature control up to 1600°C, ideal for thin film deposition. Customizable for research and industrial needs.

Split Chamber CVD Tube Furnace with Vacuum Station CVD Machine

Split Chamber CVD Tube Furnace with Vacuum Station - High precision 1200°C lab furnace for advanced materials research. Customizable solutions available.

Electric Rotary Kiln Small Rotary Furnace for Activated Carbon Regeneration

Electric Activated Carbon Regeneration Furnace by KINTEK: High-efficiency, automated rotary kiln for sustainable carbon recovery. Minimize waste, maximize savings. Get a quote!

Vertical Laboratory Quartz Tube Furnace Tubular Furnace

Precision KINTEK Vertical Tube Furnace: 1800℃ heating, PID control, customizable for labs. Ideal for CVD, crystal growth & materials testing.

High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

KT-MD Debinding & Pre-Sintering Furnace for ceramics - precise temperature control, energy-efficient design, customizable sizes. Boost your lab efficiency today!

Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

Precision Split Multi Heating Zone Rotary Tube Furnace for high-temperature material processing, featuring adjustable tilt, 360° rotation, and customizable heating zones. Ideal for labs.

1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

Discover KINTEK's 1200℃ Split Tube Furnace with quartz tube for precise high-temperature lab applications. Customizable, durable, and efficient. Get yours now!

1400℃ Muffle Oven Furnace for Laboratory

KT-14M Muffle Furnace: Precision 1400°C heating with SiC elements, PID control, and energy-efficient design. Ideal for labs.

1200℃ Muffle Oven Furnace for Laboratory

KINTEK KT-12M Muffle Furnace: Precision 1200°C heating with PID control. Ideal for labs needing rapid, uniform heat. Explore models & customization options.

Laboratory Muffle Oven Furnace with Bottom Lifting

Boost lab efficiency with KT-BL Bottom Lifting Furnace: precise 1600℃ control, superior uniformity, and enhanced productivity for material science and R&D.