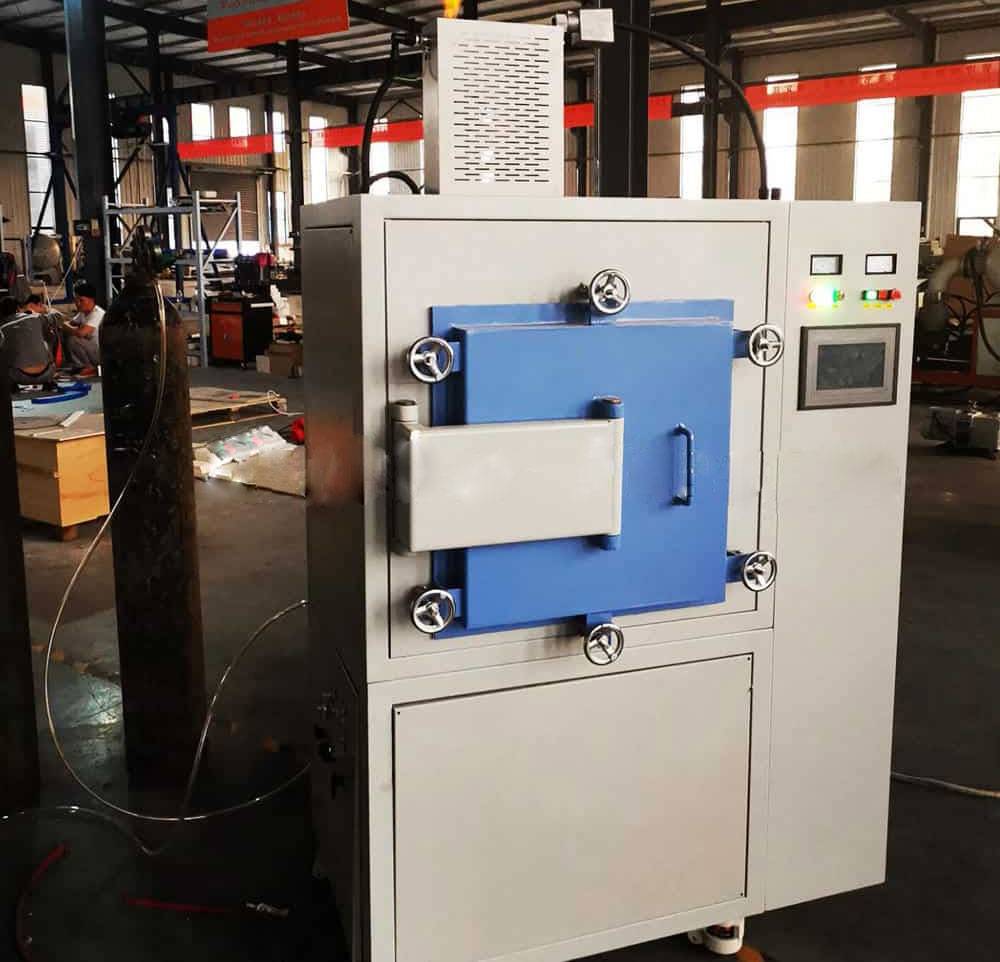

Atmosphere Furnace

Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

Item Number : KT-16AH

Price varies based on specs and customizations

- Max. temperature

- 1600℃

- Heating element

- Molybdenum wire

- Temperature control accuracy

- ±1℃

Shipping:

Contact us to get shipping details Enjoy On-time Dispatch Guarantee.

Why Choose Us

Reliable PartnerEasy ordering process, quality products, and dedicated support for your business success.

Explore the Hydrogen Atmosphere Furnace: Details & Parts

Advanced Hydrogen Atmosphere Furnace by KINTEK

The KINTEK Hydrogen Atmosphere Furnace is a specialized heating device engineered for precise sintering or annealing of materials in a controlled hydrogen or inert gas environment, with temperatures adjustable up to 1600°C. Leveraging our exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories and industrial facilities with advanced high-temperature furnace solutions. This furnace embodies our commitment to quality, featuring a robust double-shell structure with integrated air and water cooling systems, high-purity molybdenum wire heating elements for uniform heating, and advanced safety mechanisms including automatic hydrogen tail gas ignition and pressure control systems.

Ideal for processing sensitive materials like optical materials and titanium alloys, this furnace ensures precise, safe, and efficient operation in reducing or inert gas atmospheres. Our extensive product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD/MPCVD Systems, is complemented by our strong deep customization capability to precisely meet your unique experimental and production requirements.

Key Features for Optimal Performance and Safety

The Hydrogen Atmosphere Furnace is designed with cutting-edge features to provide precise environmental control and ensure operational safety during critical sintering or annealing processes. This furnace is particularly beneficial for materials requiring processing in a hydrogen or inert gas atmosphere.

- Robust Double-Shell Structure with Advanced Cooling: Features a double-layer shell design with both air and water cooling systems. This maintains stable internal pressures from 0.02MPa (positive) to -0.1MPa (negative), crucial for optimal material processing.

- High-Precision Gas Flow Control: Equipped with two large-range flow meters for nitrogen and hydrogen (each 0-3.5L/min), allowing for meticulous control over gas flow rates. This is vital for maintaining the desired atmospheric composition and achieving consistent, high-quality results.

- Comprehensive Hydrogen Safety System: Prioritizing safety, the furnace includes an automatic hydrogen tail gas ignition system. If ignition fails, it automatically cuts off hydrogen supply, opens the nitrogen valve, and purges the furnace with nitrogen, preventing hazardous conditions.

- Superior Heating with High-Purity Molybdenum Elements: Utilizes 99.99% pure molybdenum wire for its heating elements, ensuring uniform, efficient heating critical for high-quality sintering and annealing.

- Wide Temperature Versatility: Offers an adjustable working temperature range from ambient up to 1600°C, accommodating a diverse array of materials and processes for both laboratory research and industrial applications.

Versatile Applications Across Industries

The Hydrogen Atmosphere Furnace is specialized equipment designed for various high-temperature processes requiring a meticulously controlled environment, particularly with hydrogen or inert gases. It is ideal for applications where preventing oxidation or other chemical reactions is crucial, ensuring the integrity and quality of processed materials.

- Sintering of Advanced Materials: Perfect for consolidating powders into solid materials, especially for high-performance ceramics and metals that demand specific atmospheres to prevent oxidation.

- Annealing Processes: Used for controlled heating and cooling of materials, particularly metals, to remove internal stresses, soften materials, or alter electrical properties.

- Heat Treatment of Titanium Alloys: Essential for thermally processing titanium and its alloys in a controlled hydrogen or inert gas environment to enhance mechanical properties and prevent surface contamination.

- Processing of Optical Materials: Highly useful for sintering and annealing optical materials like phosphors and other luminescent substances that need a clean, controlled atmosphere to maintain optical clarity and performance.

- Research and Development: Widely employed in laboratories and research facilities for experiments involving high-temperature reactions in controlled atmospheres, aiding in the development of new materials and processes.

- Manufacturing of Electronic Components: Critical for producing semiconductors and other electronic components that require precise temperature control and a clean environment for high performance and reliability.

Principle of Operation

Hydrogen atmosphere furnaces utilize a ceramic tube with leak-tight flanges to enable heat treatment up to 1600 °C in a hydrogen atmosphere. Prior to introducing hydrogen gas, the tube is flooded with inert gas for safety. The flooding tank system, pressurized with inert gas, purges remaining oxygen from the tube before heat treatment. The gas outlet system connects to an afterburner to combust outgoing hydrogen. Exothermic hydrogen atmospheres reduce surface oxides, improving the wetting properties and flow of filler material during brazing.

Advantages of KINTEK's Hydrogen Atmosphere Furnace

Choosing KINTEK's Hydrogen Atmosphere Furnace provides significant benefits, making it a superior choice for your high-temperature processing needs:

- Enhanced Oxygen Exclusion: The pressurized environment and robust sealing ensure that oxygen cannot enter, providing a completely controlled atmosphere vital for sensitive processes and material integrity.

- Maximized Reductive Power: The availability of more reactive hydrogen molecules, compared to partial pressure atmospheres, maximizes reductive power, crucial for processes requiring a strong reducing environment.

- Versatility with Gas Mixtures: Offers the flexibility to use mixtures of inert gases (like nitrogen or argon) with hydrogen, retaining reducing capabilities while potentially optimizing operating and investment costs.

- Advanced Safety and Reliability: Equipped with a fully automated flow controller and safety devices adhering to SIL2 standards. A hydrogen sensor at the top of the furnace provides immediate response to leaks, triggering a switch to inert gas and securing the system.

- User-Friendly Operation: An intuitive touch panel interface simplifies operation and control, making the furnace accessible to users of varying technical expertise.

- Adaptable to Your Needs: Can be adapted for different usable spaces and temperatures. Cold wall furnace options are available for requirements exceeding 1800 °C, showcasing our customization capabilities.

- Superior Sealing Efficiency: A high-temperature-resistant silica gel seal ring on the furnace door ensures excellent sealing, allowing for vacuum creation and various other atmospheres, enhancing the furnace's versatility.

Technical Specifications

| Furnace model | KT-16AH | ||

|---|---|---|---|

| Max. temperature | 1600℃ | ||

| Constant work temperature | 1500℃ | ||

| Vacuum pressure | 0.1Mpa | ||

| Vacuum valve | Needle valve | ||

| Chamber material | Japan alumina fiber | ||

| Heating element | Molybdenum wire | ||

| Heating rate | 0-20℃/min | ||

| Temperature sensor | B type thermal couple | ||

| Temperature controller | Touch screen PID controller | ||

| Temperature control accuracy | ±1℃ | ||

| Temperature uniformity | ±5℃ | ||

| Electric power supply | AC110-220V,50/60HZ | ||

| Standard Chamber Sizes Stocks | |||

| Chamber size (mm) | Effective volume (L) | Chamber size (mm) | Effective volume (L) |

| 150x150x200 | 4.5 | 300x300x400 | 36 |

| 200x200x300 | 12 | 400x400x400 | 64 |

| Customer design sizes and volume is accepted | |||

| Standard Temperature controlling |

|

|---|---|

| Optional of Temperature controlling |

|

| Furnace structure | Double layer steel casing with dual cooling fan, surface temperature below 60℃ |

| Furnace door |

|

| Warranty |

|

| Hydrogen Furnace Using Attentions |

|

Tailor Your Furnace Solution with KINTEK

At KINTEK, we understand that unique experimental and production requirements demand tailored solutions. Our Hydrogen Atmosphere Furnace can be customized to meet your specific needs, from chamber size and temperature ranges to specialized control systems. Our team of experts is ready to discuss your application and help design the perfect furnace configuration for you.

Ready to enhance your high-temperature processes?

Contact us today to learn more about the Hydrogen Atmosphere Furnace, discuss your customization needs, or request a quote. Let KINTEK's expertise in advanced furnace technology empower your research and production.

Get in Touch for a Custom Solution

FAQ

What Is An Atmosphere Furnace Used For?

What Are The Key Features Of An Atmosphere Furnace?

How Does An Atmosphere Furnace Work?

What Are The Advantages Of Using An Atmosphere Furnace?

What Types Of Gases Can Be Used In An Atmosphere Furnace?

What Safety Features Are Available In Advanced Atmosphere Furnaces?

4.8

out of

5

Incredible precision and durability! The furnace maintains perfect atmosphere control, a game-changer for our lab.

4.7

out of

5

Fast delivery and top-notch quality. This furnace has significantly improved our research efficiency.

4.9

out of

5

Worth every penny! The advanced technology ensures consistent results every time.

4.8

out of

5

Superior build and performance. The inert atmosphere control is flawless, highly recommended!

4.7

out of

5

Excellent value for money. The furnace is robust and delivers precise results effortlessly.

4.9

out of

5

Cutting-edge technology! This furnace has revolutionized our material testing processes.

4.8

out of

5

Reliable and efficient. The nitrogen-hydrogen atmosphere control is impeccable.

4.7

out of

5

Quick setup and outstanding performance. A must-have for any serious laboratory.

4.9

out of

5

Exceptional durability and precision. This furnace exceeds all expectations.

4.8

out of

5

Top-tier quality and innovation. The furnace’s atmosphere control is unmatched.

4.7

out of

5

Fantastic investment! The furnace delivers consistent, high-quality results with ease.

REQUEST A QUOTE

Our professional team will reply to you within one business day. Please feel free to contact us!

Related Products

1700℃ Controlled Inert Nitrogen Atmosphere Furnace

KT-17A Controlled Atmosphere Furnace: Precise 1700°C heating with vacuum & gas control. Ideal for sintering, research & material processing. Explore now!

1400℃ Controlled Inert Nitrogen Atmosphere Furnace

KT-14A Controlled Atmosphere Furnace for labs & industry. 1400°C max temp, vacuum sealing, inert gas control. Customizable solutions available.

1200℃ Controlled Inert Nitrogen Atmosphere Furnace

KINTEK 1200℃ Controlled Atmosphere Furnace: Precision heating with gas control for labs. Ideal for sintering, annealing, and material research. Customizable sizes available.

Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

KINTEK Mesh Belt Furnace: High-performance controlled atmosphere furnace for sintering, hardening & heat treatment. Customizable, energy-efficient, precise temperature control. Get a quote now!

Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

KINTEK's CVD Tube Furnace offers precision temperature control up to 1600°C, ideal for thin film deposition. Customizable for research and industrial needs.

Split Chamber CVD Tube Furnace with Vacuum Station CVD Machine

Split Chamber CVD Tube Furnace with Vacuum Station - High precision 1200°C lab furnace for advanced materials research. Customizable solutions available.

Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

KINTEK's Multi-Zone CVD Tube Furnaces offer precision temperature control for advanced thin film deposition. Ideal for research and production, customizable for your lab needs.

Laboratory Muffle Oven Furnace with Bottom Lifting

Boost lab efficiency with KT-BL Bottom Lifting Furnace: precise 1600℃ control, superior uniformity, and enhanced productivity for material science and R&D.

1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

Discover KINTEK's 1200℃ Split Tube Furnace with quartz tube for precise high-temperature lab applications. Customizable, durable, and efficient. Get yours now!

Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

Precision Split Multi Heating Zone Rotary Tube Furnace for high-temperature material processing, featuring adjustable tilt, 360° rotation, and customizable heating zones. Ideal for labs.

Electric Rotary Kiln Small Rotary Furnace for Activated Carbon Regeneration

Electric Activated Carbon Regeneration Furnace by KINTEK: High-efficiency, automated rotary kiln for sustainable carbon recovery. Minimize waste, maximize savings. Get a quote!

1800℃ High Temperature Muffle Oven Furnace for Laboratory

KINTEK Muffle Furnaces: Precision 1800°C heating for labs. Energy-efficient, customizable, with PID control. Ideal for sintering, annealing, and research.

1400℃ Muffle Oven Furnace for Laboratory

KT-14M Muffle Furnace: Precision 1400°C heating with SiC elements, PID control, and energy-efficient design. Ideal for labs.

1200℃ Muffle Oven Furnace for Laboratory

KINTEK KT-12M Muffle Furnace: Precision 1200°C heating with PID control. Ideal for labs needing rapid, uniform heat. Explore models & customization options.

High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

KT-MD Debinding & Pre-Sintering Furnace for ceramics - precise temperature control, energy-efficient design, customizable sizes. Boost your lab efficiency today!

Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

KINTEK's PECVD coating machine delivers precision thin films at low temperatures for LEDs, solar cells & MEMS. Customizable, high-performance solutions.

High Performance Vacuum Bellows for Efficient Connection and Stable Vacuum in Systems

KF ultra-high vacuum observation window with high borosilicate glass for clear viewing in demanding 10^-9 Torr environments. Durable 304 stainless steel flange.

Stainless Steel Quick Release Vacuum Chain Three Section Clamp

Stainless steel quick release vacuum clamps ensure leak-free connections for high vacuum systems. Durable, corrosion-resistant, and easy to install.

Ultra Vacuum Electrode Feedthrough Connector Flange Power Lead for High Precision Applications

Ultra-Vacuum Electrode Feedthroughs for reliable UHV connections. High-sealing, customizable flange options, ideal for semiconductor & space applications.