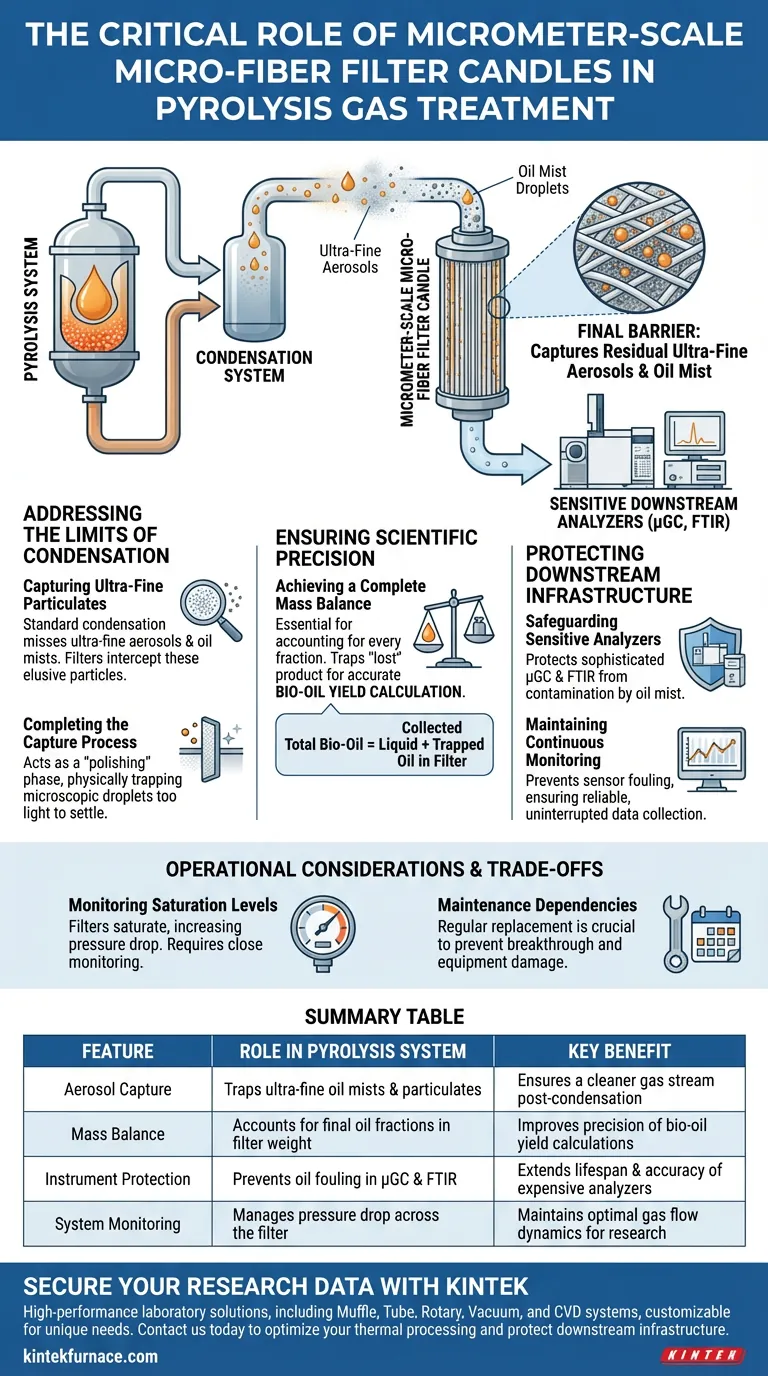

Micrometer-scale micro-fiber filter candles serve as a critical final barrier in pyrolysis cooling systems. Their primary function is to capture residual ultra-fine aerosols and oil mist particles that have persisted through the initial condensation stages, ensuring the gas stream is sufficiently clean before it reaches sensitive analysis equipment.

Pyrolysis gases often retain elusive oil mists even after standard cooling. Implementing these fine filters ensures a precise mass balance calculation for bio-oil yield while simultaneously protecting sensitive downstream analyzers from costly contamination and fouling.

Addressing the Limits of Condensation

While cooling systems effectively condense the majority of vapors into liquid bio-oil, they are rarely 100% efficient at capturing the finest particulates.

Capturing Ultra-Fine Particulates

Standard condensation trains often allow ultra-fine aerosols and oil mists to remain entrained in the gas stream. Micrometer-scale filters are specifically installed at the end of the cooling system to intercept these remaining particles.

Completing the Capture Process

This filtration step acts as a "polishing" phase. It physically traps the microscopic droplets that are too light to settle out during the primary cooling process.

Ensuring Scientific Precision

The use of filter candles is not just about cleanliness; it is a requirement for data integrity in pyrolysis studies.

Achieving a Complete Mass Balance

In experimental pyrolysis, accounting for every fraction of the product spectrum is essential. Any oil mist that escapes with the gas represents "lost" product.

By trapping these final traces of oil, the filters allow for a highly accurate calculation of the total collected bio-oil. Without them, the mass balance data would be skewed, leading to an underestimation of liquid yields.

Protecting Downstream Infrastructure

Perhaps the most critical operational role of these filters is the defense of expensive analytical hardware located downstream.

Safeguarding Sensitive Analyzers

The gas stream is typically routed to sophisticated instruments such as online micro-gas chromatographs ($\mu$GC) and Fourier-transform infrared (FTIR) spectrometers.

These devices rely on pristine gas samples to function correctly. Even small amounts of oil mist can contaminate the internal components of these instruments.

Maintaining Continuous Monitoring

Contamination does not just damage equipment; it disrupts data continuity.

If sensors become fouled by oil, the accuracy of online gas composition monitoring is compromised. The filter candles ensure the gas entering these devices is dry and particulate-free, guaranteeing reliable, uninterrupted data collection.

Operational Considerations and Trade-offs

While filter candles are essential for protection and accuracy, they introduce specific operational dynamics that must be managed.

Monitoring Saturation Levels

Because these filters are designed to capture "sticky" oil mists and fine particulates, they will eventually saturate.

As the filter loads, the pressure drop across the unit will increase. Operators must monitor this closely to ensure it does not negatively impact the flow dynamics of the overall pyrolysis system.

Maintenance Dependencies

The efficiency of the downstream equipment is directly tied to the condition of the filter. Neglecting filter replacement can lead to sudden breakthroughs of oil mist, instantly jeopardizing the $\mu$GC or FTIR units you intended to protect.

Optimizing Your Filtration Strategy

To ensure high-quality data and equipment safety, consider your specific operational goals when implementing these filters.

- If your primary focus is mass balance precision: Ensure the filter is weighed before and after experiments to account for the mass of the trapped oil mist in your total yield calculations.

- If your primary focus is instrument longevity: Prioritize the installation of high-efficiency filters immediately upstream of any $\mu$GC or FTIR units to strictly prevent sensor fouling.

By effectively managing these final aerosols, you secure both the integrity of your yield data and the reliability of your analytical hardware.

Summary Table:

| Feature | Role in Pyrolysis System | Key Benefit |

|---|---|---|

| Aerosol Capture | Traps ultra-fine oil mists and particulates | Ensures a cleaner gas stream post-condensation |

| Mass Balance | Accounts for final oil fractions in filter weight | Improves the precision of bio-oil yield calculations |

| Instrument Protection | Prevents oil fouling in $\mu$GC and FTIR units | Extends lifespan and accuracy of expensive analyzers |

| System Monitoring | Manages pressure drop across the filter | Maintains optimal gas flow dynamics for research |

Secure Your Research Data with KINTEK

Don’t let oil mist contamination compromise your pyrolysis yields or damage your expensive analytical equipment. Backed by expert R&D and manufacturing, KINTEK offers high-performance laboratory solutions—including Muffle, Tube, Rotary, Vacuum, and CVD systems—all customizable for your unique experimental needs.

Our specialized high-temperature furnaces and filtration components ensure the precision and durability your lab demands. Contact us today to discuss how our tailored engineering can optimize your thermal processing and protect your downstream infrastructure.

Visual Guide

References

- Hoda Shafaghat, Olov Öhrman. Customized Atmospheric Catalytic Hydropyrolysis of Biomass to High-Quality Bio-Oil Suitable for Coprocessing in Refining Units. DOI: 10.1021/acs.energyfuels.3c05078

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- CF KF Flange Vacuum Electrode Feedthrough Lead Sealing Assembly for Vacuum Systems

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant Rotating Furnace

People Also Ask

- What are the common types and size ranges of Alumina ceramic tubing? Find the Perfect Fit for Your Lab

- What are the advantages of using alumina (Al2O3) crucibles for the high-temperature pyrolysis of Bakelite?

- How does a laboratory drying oven function in catalyst synthesis? Secure Precision Metal Precursor Stabilization

- What process challenges are addressed by vacuum filtration equipment during the construction of CsPbBr3@CA-SiO2 films?

- What is the purpose of using a high-purity quartz boat? Ensure Sample Purity in TiO2@C High-Temp Annealing

- Why is a vacuum pump utilized in research concerning the reaction of magnesium with carbon dioxide and nitrogen? Ensure Data Integrity

- Why is a PTFE-lined stainless steel autoclave used for Ni12P5 synthesis? Key Benefits for Nanomaterial Production

- Why use high-purity MgO crucibles at 1400°C? Secure Chemical Isolation and Data Integrity in Desulfurization