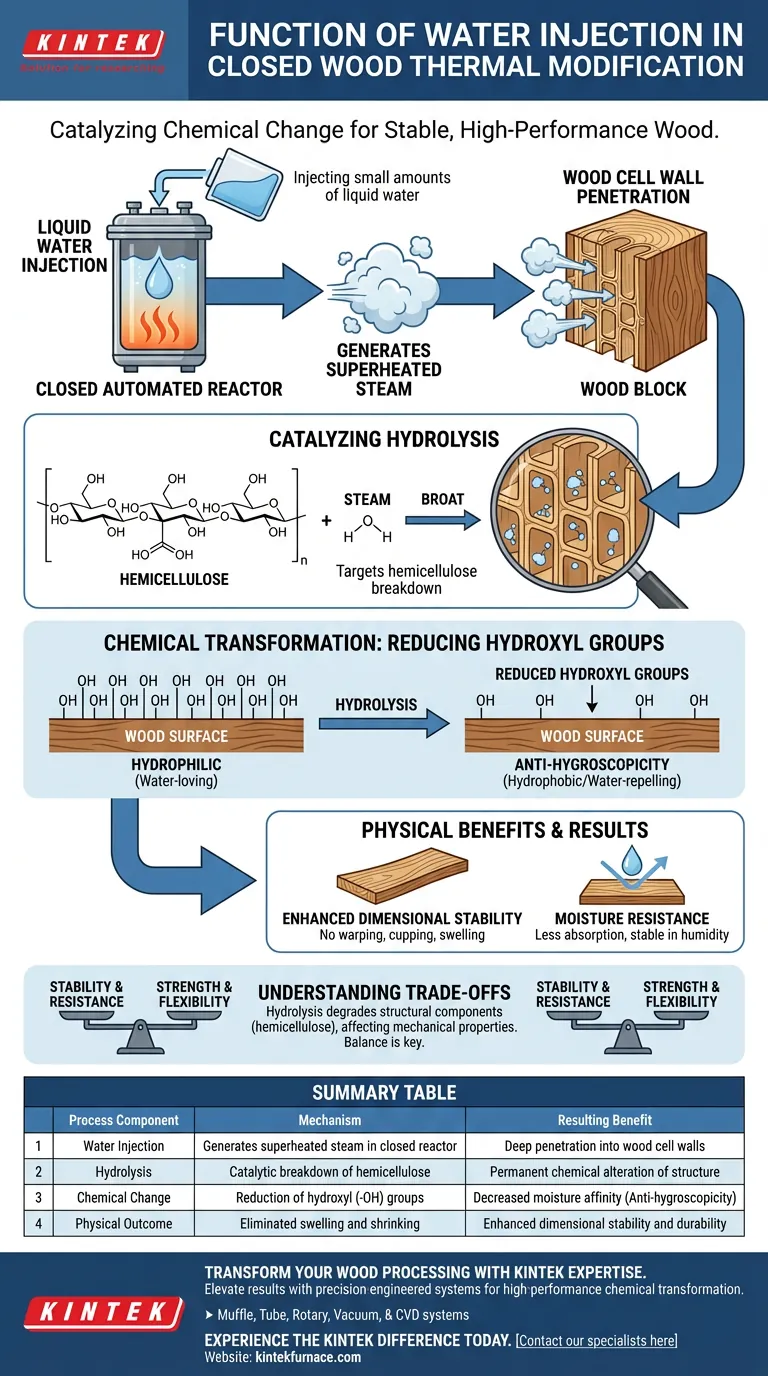

The primary function of injecting liquid water is to generate superheated steam, which acts as a catalyst for chemical modification. Upon entering the heated, automated reactor, the water vaporizes and accelerates the hydrolysis of hemicellulose within the wood. This reaction is the critical mechanism that permanently alters the wood's properties, rather than simply drying it.

By facilitating the hydrolysis of hemicellulose, the injected water reduces the number of hydroxyl groups on the wood's surface. This fundamental chemical change significantly improves the wood's dimensional stability and resistance to moisture absorption (anti-hygroscopicity).

The Mechanism of Action

Generation of Superheated Steam

When small amounts of liquid water are injected into the closed reactor during the heating process, the intense heat instantly converts the liquid into gas.

Because the system is closed and heated, this vapor becomes superheated steam. This state allows the steam to penetrate the wood structure deeply and interact with its chemical components.

Catalyzing Hydrolysis

The superheated steam serves a specific chemical purpose beyond heat transfer. It acts as a catalyst for hydrolysis.

This reaction targets the wood's chemical structure, specifically breaking down hemicellulose, which is the most thermally unstable polymer in the wood cell wall.

Chemical Transformation of the Wood

Reducing Hydroxyl Groups

The most significant outcome of this catalytic hydrolysis is the reduction of hydroxyl groups (-OH).

Hydroxyl groups are responsible for wood's natural affinity for water. They act as "hooks" that grab onto moisture from the air.

By degrading the hemicellulose and reducing these groups, the process essentially removes the sites where water would normally bind to the wood.

Achieving Anti-Hygroscopicity

With fewer hydroxyl groups available, the wood loses its ability to absorb moisture from the environment.

This property is known as anti-hygroscopicity. The modified wood becomes "hydrophobic," repelling water rather than absorbing it like a sponge.

Physical Benefits and Results

Enhanced Dimensional Stability

Because the wood no longer absorbs or releases significant amounts of moisture, it stops expanding and contracting with changes in humidity.

This results in superior dimensional stability, meaning the wood is far less prone to warping, cupping, or swelling after installation.

Understanding the Trade-offs

The Cost of Hydrolysis

While the hydrolysis of hemicellulose is beneficial for stability, it is a degradation process.

The same reaction that stops the wood from moving involves breaking down structural components of the cell wall.

Strength vs. Stability

It is important to acknowledge that altering the chemical structure to repel water often impacts other physical properties.

The removal of hemicellulose chains can alter the mechanical flexibility of the wood. The process must be carefully controlled to balance the gain in stability against potential changes in brittleness or strength.

Making the Right Choice for Your Goal

To maximize the benefits of thermal modification, consider your specific performance requirements:

- If your primary focus is Dimensional Stability: Prioritize processes that ensure sufficient water injection to maximize the hydrolysis of hemicellulose and the reduction of hydroxyl groups.

- If your primary focus is Moisture Resistance: Verify that the reactor protocols maintain the superheated steam environment long enough to achieve high anti-hygroscopicity levels.

Injecting water is not merely about managing temperature; it is the chemical trigger that transforms wood into a stable, high-performance material.

Summary Table:

| Process Component | Mechanism | Resulting Benefit |

|---|---|---|

| Water Injection | Generates superheated steam in closed reactor | Deep penetration into wood cell walls |

| Hydrolysis | Catalytic breakdown of hemicellulose | Permanent chemical alteration of structure |

| Chemical Change | Reduction of hydroxyl (-OH) groups | Decreased moisture affinity (Anti-hygroscopicity) |

| Physical Outcome | Eliminated swelling and shrinking | Enhanced dimensional stability and durability |

Transform Your Wood Processing with KINTEK Expertise

Elevate your thermal modification results with precision-engineered systems designed for high-performance chemical transformation. Backed by expert R&D and manufacturing, KINTEK offers a wide range of laboratory solutions including Muffle, Tube, Rotary, Vacuum, and CVD systems, all fully customizable to meet your unique research or production needs.

Whether you are refining hydrolysis protocols or scaling up advanced thermal treatments, our high-temperature furnaces provide the control and reliability your project demands. Experience the KINTEK difference today—Contact our specialists here to discuss your custom furnace requirements!

Visual Guide

References

- Guntis Sosins, Jānis Zicāns. Water-Related Properties of Wood after Thermal Modification in Closed Process under Pressure in Nitrogen. DOI: 10.3390/f15010140

This article is also based on technical information from Kintek Furnace Knowledge Base .

People Also Ask

- What is the purpose of using high-purity argon gas for NAB alloys? Ensure Superior Nickel-Aluminum Bronze Integrity

- What is the use of furnace in laboratory? Unlock Precise High-Temperature Control for Material Transformations

- Why are specific temperatures of 848 K, 898 K, and 948 K selected for the Thermal Oxidation of Ti-6Al-4V ELI alloy?

- What is the temperature of a sintering furnace? From 1100°C to 2200°C+ for Your Material

- Why is precise temperature control critical for drying carbon nanotube films? Achieve Perfect 80°C Thermal Stability

- What is the function of a vacuum drying oven in the post-treatment of PPy/alpha-Fe2O3 composite materials? Expert Insights

- Why is it necessary to use a vacuum drying oven for porous graphene cathodes? Ensure Peak Battery Performance

- Why is a sample cell system with heating control necessary for the impedance analysis of yttrium-doped nickel ferrite?