Non-conductive polymer containers are essential for ensuring data integrity during piezoresistive testing. They serve a dual purpose: preventing electrical current leakage and mechanically stabilizing the bulk powder. By acting as an insulator, the container forces electrical current to flow strictly between the top and bottom electrodes, ensuring that the measured resistance is solely a result of the carbon nanoparticles' response to compression.

The use of non-conductive containers is a fundamental control measure. It isolates the electrical path to the vertical axis and mechanically constrains the powder, eliminating external variables that would otherwise corrupt resistance measurements.

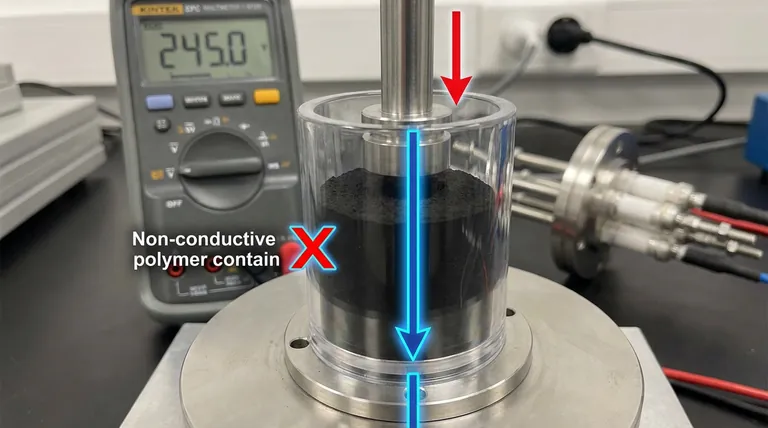

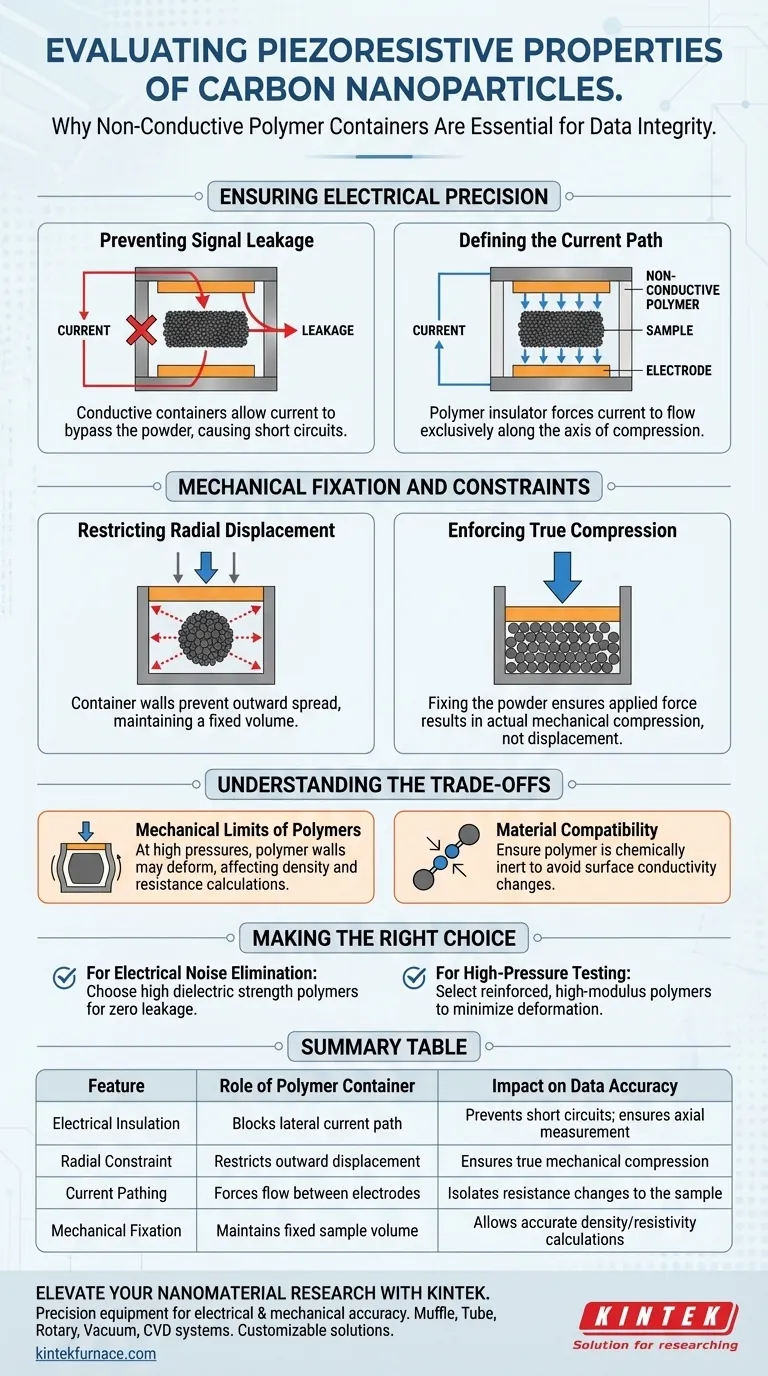

Ensuring Electrical Precision

Preventing Signal Leakage

The primary challenge in testing carbon nanoparticles is their high conductivity. If a conductive container were used, the electrical current would naturally take the path of least resistance.

This would likely involve the current bypassing the powder and traveling through the container walls. A non-conductive polymer effectively blocks this lateral path, preventing short circuits and ensuring all current passes through the test sample.

Defining the Current Path

To measure piezoresistivity accurately, you must establish a controlled electrical environment. The goal is to measure changes strictly along the axis of compression.

The polymer container acts as a barrier, forcing the current to flow exclusively between the top and bottom electrodes. This isolation ensures the data reflects the true properties of the nanoparticles, rather than artifacts of the experimental setup.

Mechanical Fixation and Constraints

Restricting Radial Displacement

When bulk powder is subjected to uniaxial pressure (compression from the top), the particles naturally attempt to spread outward laterally.

The polymer container provides the necessary mechanical fixation to prevent this. It restricts radial displacement, ensuring the powder remains contained within a fixed volume.

Enforcing True Compression

Without the containment provided by the polymer walls, the application of pressure would simply displace the particles rather than compress them.

By fixing the powder in place, the container ensures that the applied force results in actual mechanical compression of the nanoparticle structure. This physical change is what induces the resistance changes you are trying to measure.

Understanding the Trade-offs

Mechanical Limits of Polymers

While polymers are excellent insulators, they possess lower mechanical strength compared to metals or ceramics.

At extremely high pressures, the container walls themselves may deform or bulge. This deformation can alter the cross-sectional area of the sample, potentially introducing a margin of error into your density and resistance calculations.

Material Compatibility

It is vital to ensure the chosen polymer is chemically inert regarding the specific type of carbon nanoparticle being tested.

While rare in dry powder testing, any chemical interaction between the container surface and the sample could alter the surface conductivity of the particles at the boundary layer.

Making the Right Choice for Your Experiment

To ensure your piezoresistive data is valid, you must match your container choice to your specific experimental limits.

- If your primary focus is eliminating electrical noise: Prioritize polymers with high dielectric strength to guarantee zero leakage between electrodes.

- If your primary focus is high-pressure testing: Select a reinforced, high-modulus polymer to minimize container deformation and radial expansion.

Correctly isolating the sample—both electrically and mechanically—is the only way to derive reliable characteristics from carbon nanoparticles.

Summary Table:

| Feature | Role of Polymer Container | Impact on Data Accuracy |

|---|---|---|

| Electrical Insulation | Blocks lateral current path through walls | Prevents short circuits; ensures axial measurement |

| Radial Constraint | Restricts outward displacement of powder | Ensures true mechanical compression under load |

| Current Pathing | Forces flow between top/bottom electrodes | Isolates resistance changes to the nanoparticle sample |

| Mechanical Fixation | Maintains fixed sample volume | Allows for accurate density and resistivity calculations |

Elevate Your Nanomaterial Research with KINTEK

Precision in nanoparticle testing requires specialized equipment that ensures both electrical and mechanical accuracy. Backed by expert R&D and manufacturing, KINTEK offers a wide range of laboratory solutions including Muffle, Tube, Rotary, Vacuum, and CVD systems, all customizable for your unique material science needs.

Whether you are evaluating piezoresistive properties or developing next-generation carbon composites, our high-temperature furnaces and lab tools provide the stability and control your research demands.

Ready to optimize your experimental setup? Contact us today to consult with our experts on the right equipment for your lab.

Visual Guide

References

- Bruno Alderete, S. Suárez. Evaluating the effect of unidirectional loading on the piezoresistive characteristics of carbon nanoparticles. DOI: 10.1038/s41598-024-59673-5

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

People Also Ask

- Why is the use of high-alumina crucibles essential for NCM811? Ensure Purity in High-Nickel Cathode Synthesis

- What is the function of a vacuum system in PLD? Ensure High-Density, Pure Electrolyte Thin Films

- Why is radiation correction necessary for K-type thermocouple readings? Ensure Accurate High-Temp Combustion Data

- Why is the precise regulation of oxygen ratios via mass flow controllers critical for MCTV catalyst yield?

- What is the function of a high-purity porcelain crucible? Expert Guide to Chromium-Doped Borosilicate Glass Preparation

- Why are corundum crucibles selected for high-temperature annealing of LiScO2:Cr3+? Protect Purity and Performance

- What is the primary function of a drying oven during LLZTO preparation? Ensure Pure Phase Solid Electrolytes

- How do a brass cap and a cooling element work together? Ensuring Reliable High-Temperature Experimental Seals